![]()

About

Us

In 1982, Paul Meunier – a manager & entrepreneur in Canada working within the paper making and printing industry – stumbled upon a new type of tool that replaced the need for utility knives in the plant that cut things like craft outer-wrap, long jumbo rolls and roll stock, left-on spool or core material and more.

What he discovered however, was a product that had limitations. Thin flimsy plastic tips that would curl and warp under the heat generated by cutting (slabbing) long parent rolls of material. A tool that would either break or loose it’s life quickly and needed to be replaced often. A tool that wasn’t strong enough to handle the cutting of heavier materials such as paperboard, film, foil or corrugated.

He knew he could improve upon this tool – and did – with the Duckbill Roll Slabber. The name Duckbill is derived from the proprietary duckbill-shaped contour on the leading edge of the tool.

How is this an improved version of an existing tool?

Two reasons:

FIRST – The Duckbill Roll Slabber is made from a proprietary blend of heat resistant engineered themoplastic and reinforced fiberglass. This makes it both dense and strong. So dense that this tool can be “machined” with sandpaper to re-sharpen its tip. Plus, with a melting point of 480°F it will not soften, melt or curl like a typical plastic tool. In fact, because of these attributes, it outlasts plastic slabbers 5:1 on paperboard and boxboard webs, and 8:1 on lightweight paper, film and foil webs.

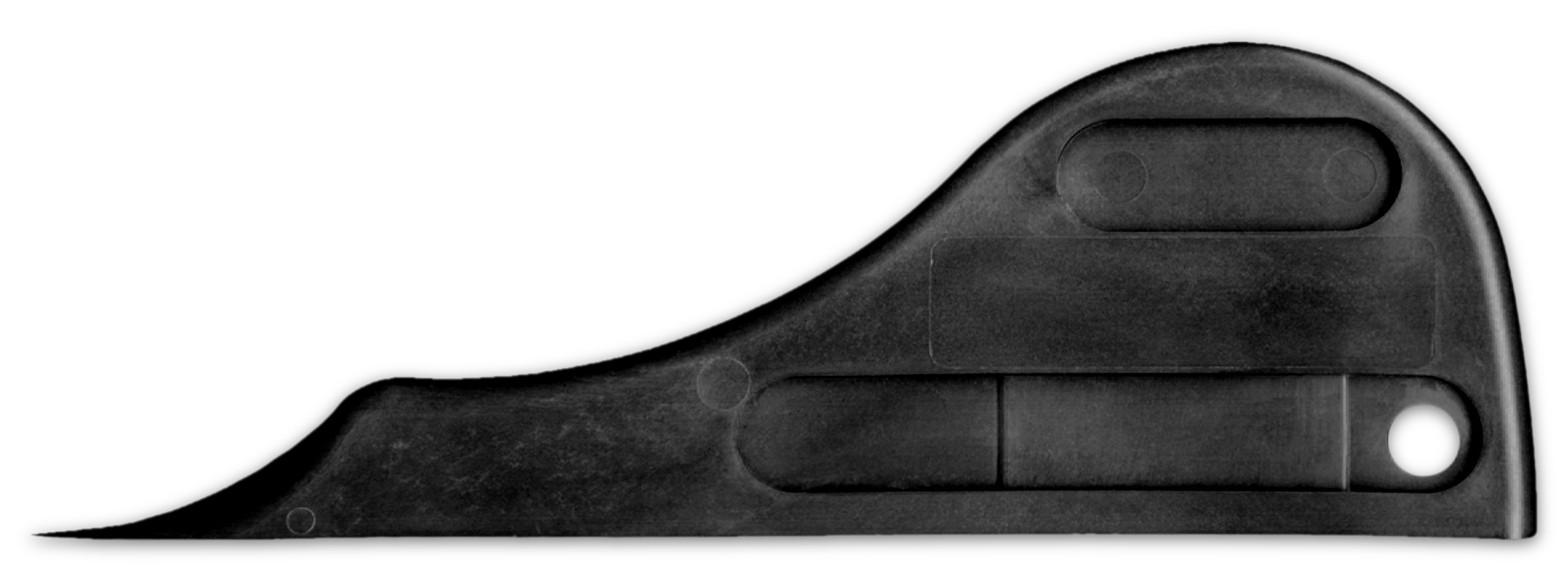

SECOND – The designed set of curves on the leading edge of the Duckbill Roll Slabber and its engineered radius work to first lift and then separate the plies of paper, film, foil or board for an easy, straight and clean peel and cut. Plus, the design ergonomically optimizes slabbing power without compromising control.

Principal Features and Benefits

-

- Proprietary Duckbill shaped nose easily and precisely slips into position under any outer wrap and the first wrap of useable material preventing damage and eliminating usable waste.

- The flat bottom base of the tool is designed to distribute cutting force forward, not down – promoting a “gliding” action that can prevent material scoring or damage.

- The Duckbill nose shape spreads the wrap away from the work.

- An ergonomic shaped heel that when nested in the palm of the user’s hand has a cutting force that is directed forward. (Some slabbers with a grip handle promote “over-the-top” forces that cause the nose to dip then bite, dig or score and damage any useable material.)

- Principal thermoplastic material used won’t fray, splinter or break and will hold its edge longer than ordinary plastics.

If you’re still using a blade in your plant, you may want to consider switching to a slabber.

The benefits are many, including:

-

- Open or clean up roll stock without cutting through the outer wrap and scoring or destroying valuable and usable material below.

- Remove left-on core material without cutting or scoring the re-usable core.

- Reduce or eliminate steel blade damage to reel spools.

- Eliminate cut and slice injuries form steel blades and knives.

The general shape of the Duckbill Roll Slabber works to first lift and then separate the plies of material. The flat bottom distributes the cutting force forward. The rounded shoulder allows for optimum ergonomic use, and the parting ridge of the nose shears the outer material only and nothing beneath it.

Clean up roll stock or shear material without cutting through and wasting the useable material below.

The tapered nose easily inserts precisely between roll stock outer-wrap and valuable material.

The strong, dense engineered plastic/fiberglass material allows for re-sharpening the tip leading to longer tool life.

Duckbill Enterprises Inc. | 90 rue St-Hilaire | Trois-Rivières | Québec, Canada G8V 2J8 | (819) 374-4464