Superior Engineering

Longer Lasting

Greater ROI

Fewer Injuries

The Duckbill Roll Slabber

We call it a ROLL SLABBER, but this type of cutting tool goes by many names by different users. Some call it a paper slabber, paper roll slabber, or reel slabber. At times it’s called a paper stripper or roll stock stripper or roll cutter. It’s even known as a ripper or core slabber.

Regardless of what it’s called, it serves one purpose –and that’s to cut a variety of materials (paper, film, foil, containerboard & corrugated, folding cartons, craft outer-wrap, and more) in a way that is not only safer than a utility knife (no cut or slice wounds), but is also more cost effective (less material waste or machine damage).

Although this type of tool has been around for a while and is made by a variety of manufacturers, QUALITY DOES MAKE A DIFFERENCE.

HOW WE’RE DIFFERENT

AND WHY IT WORKS

The Duckbill Roll Slabber is different than similar products for two primary reasons: how it’s engineered, and the material from which it’s made.

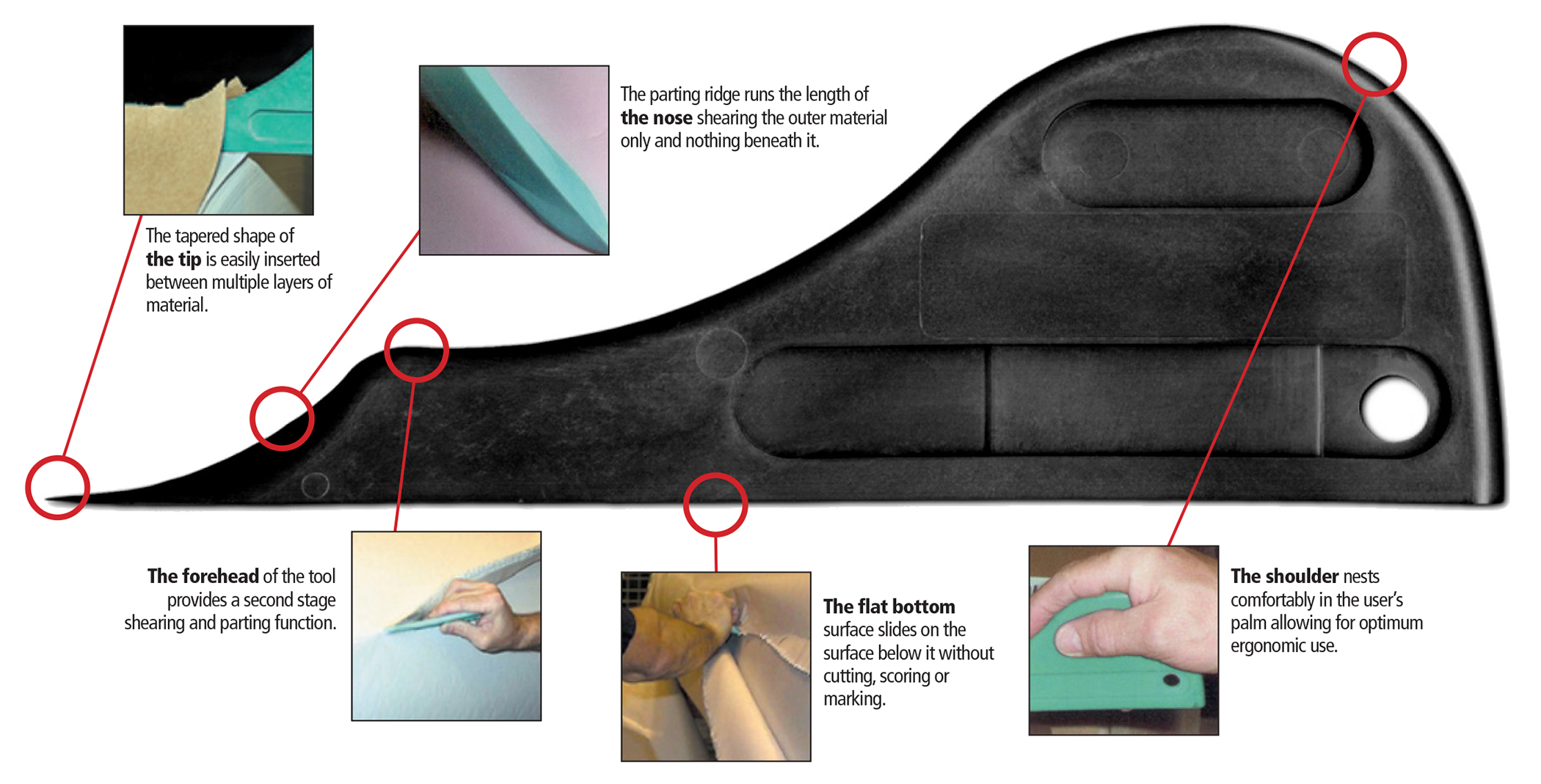

As illustrated below, the engineering of the tip, the nose, the forehead, the shoulder and the flat bottom all contribute to making this a superior product for shearing, cutting and stripping a multitude of materials.

(Click the image above to enlarge)

Engineered from a specialized and proprietary plastic/fiberglass material, the Duckbill Roll Slabber can withstand the high temperatures generated from the friction of slabbing long rolls of material and won’t soften or melt.

In addition, the tip can be re-sharpened, making this tool last longer than anything similar on the market. In fact, it outlasts typical plastic strippers 5:1 on paperboard and boxboard webs, and 8:1 on lightweight paper, film and foil webs.

FEATURES

Engineered to promote optimum lift, separation, and slice action.

Won’t score expensive reel spools or shaft surfaces.

Thermoplastic material stands up to high temperatures (to 480º F) without softening or melting from friction-generated heat.

Engineered plastic/fiberglass material is both hard and dense to hold an edge longer.

Increases yield by sliding precisely under material, preventing damage and eliminating waste.

Won’t fray, splinter or break.

TIp can be sanded to extend tool life.

Ergonomic heel design reduces hand and arm fatigue.

BENEFITS

PRECISE SLABBING – Less material waste.

LONGER LIFE – Fewer purchases resulting in greater return on your investment.

SAFER THAN BLADES. – Reduces injuries.

Duckbill Enterprises Inc. | 90 rue St-Hilaire | Trois-Rivières | Québec, Canada G8V 2J8 | (819) 374-4464